Register Link for PAYESH SANAT KAVIR Courses

ثبت نام در دورههای پایش صنعت کویر

Training with testing AND Analysis

تقویم آموزشی دوره های داخلی

Payesh Sanat Kavir Course Calendar

Register Link for PAYESH SANAT KAVIR Courses

ثبت نام در دورههای پایش صنعت کویر

Training with testing AND Analysis

تقویم آموزشی دوره های داخلی

Payesh Sanat Kavir Course Calendar

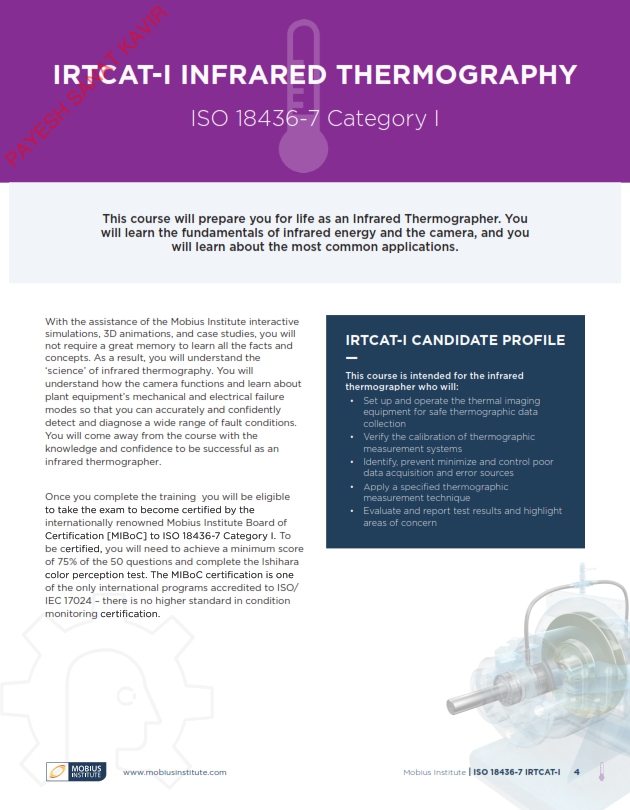

| Duration |

|---|

| ۳۲ hours, typically cwer four days |

| Format |

|---|

| Live public course |

| On-site course |

| Virtual online course |

| Video distance learning online courses and Life Long Learning (LCL) access |

| Compliance |

|---|

| Training and certification: ISO 18436-7 |

| certification: ISO 18436-1. ISO/IEC 17024 |

| Training: ISO 18436-3 |

| Exam |

|---|

| Two hours |

| SO multiple-choice questions |

| ۷۵% passing grade |

| Can be taken online or in-person at the course |

| Certification requirements |

|---|

| Training course completed |

| ۱۲-months of work experience. verified by an independent person |

| Pass the Ishihara color perception test |

| Valid for S years |

| Pre-study |

|---|

| Access to the “Learning Zone” upon registration and payment |

| Complete set of videos covering every topic |

| An excellent way to be prepared and get the most from the course |

| Post-study |

|---|

| Continue to access the Learning Zone for 4-months after the course or upgrade your access for a lifetime with Life Long Learning (LCL) |

| Continue learning. without charge. on MOBIL’S CONNECT’ via WWWMOBIUSCONNECT.COM |

| Maintenance practices |

|---|

| Reactive, preventive, condition-based, proactive |

| How to decide between them |

| Condition monitoring |

|---|

| Why it works |

| Vibration, ultrasound, oil analysis, wear particle analysis, and electric motor testing |

| Detecting faults, root causes, and quality control |

| Principles of infrared thermography |

|---|

| understanding the difference between heat energy and temperature |

| The laws of thermodynamics |

| Heat transfer modes – conduction, convection and radiation |

| The thermal capacity of different materials |

| Thermal conduction |

|---|

| The fundamentals of conduction |

| Conductive heat transfer rate |

| Thermal conductivity of different materials |

| Thermal convection |

|---|

| The fundamentals of convection |

| Compensating for the “wind cooling effect” |

| Thermal radiation |

|---|

| The fundamentals of radiation |

| Emitted, reflected and transmitted radiation |

| Radiation wavelengths and the electromagnetic spectrum |

| Emissivity and the Stefan-Boltzmann Law |

| Incident and exitant radiation |

| Equipment and data acquisition |

|---|

| Understanding the infrared camera |

| Lenses and lens materials |

| Capturing and controlling the image with temperature range, level and span |

| Color palette selection |

| Error source recognition, prevention and control |

| Calibrating the thermal camera |

| Environmental and operational conditions |

| Image storage and management |

| Safety rules and guidelines |

|---|

| Hazard awareness |

| Standards and guides |

| Personal Protective Equipment (PPE) |

| Thermographic applications |

|---|

| The basic principles of diagnostics (ISO 13379) and prognostics (ISO 13381) |

| Machinery engineering principles |

| Electrical application – fuses, transformers, switchgear, transmission lines etc |

| Mechanical application – pipes, tanks, refractories, heat exchangers etc |

| Civil applications – windows, air leaks, construction integrity etc |

| Process applications – steam traps |

| General image interpretation guidelines |

|---|

| Image processing |

| Fault classification |

| Report generation |

|---|

| Providing actionable information |

| #BallMill |

| #VibrationAnalysisCATI |

| #VibrationAnalysisCATII |

| #VibrationAnalysisCATIII |

| #VibrationAnalysisCATIV |

| #ExperimentalModalAnalysis |

| #OperationalModalAnalysis |

| #SPM |

| #ISO184362 |

| #ElectroFAN |

| #MixerElectroGearbox |

| #ElectroMotor |

| #Emerald |

| #EMA |

| #Blower |

| #BentyNavada |

| #Bearing |

| #Refineries |

| #PayeshSanatKavirInstitute |

| #ConditionMonitoringWatertreatment |

| #ConditionMonitoringSagMill |

| #ConditionMonitoringBallMill |

| #ConditionMonitoringBearing |

| #BearingVibrationConditionMonitoring |

| #ConditionMonitoringReverseOsmosis |

| #ConditionMonitoringElectroFAN |

| #ConditionMonitoringMixerGearbox |

| #ConditionMonitoringElectroMotor |

| #ConditionMonitoringBlower |

| #ConditionMonitoringBentlyNevada |

| #RollingBearingConditionMonitoring |

| #JournalBearingConditionMonitoring |

| #ConditionMonitoringRefineries |

| #ConditionMonitoringPetroleum |

| #ConditionMonitoringpump |

| #ConditionMonitoringHPPump |

| #ConditionMonitoringpumping |

| #ConditionMonitoringwaterpurification |

| #ConditionMonitoringTurbine |

| #ConditionMonitoringPelletizingdiscs |

| #ConditionMonitoringScreen |

| #ConditionMonitoringprotectionsystems |

| #ConditionMonitoringBently3500 |

| #ConditionMonitoringVM600 |

| #ConditionMonitoringCementIndustry |

| #ConditionMonitoringIndustry |

| #ConditionMonitoringRevitalization |

| #ConditionMonitoringFiber |

| #ConditionMonitoringpackagin |

| #ConditionMonitoringCondensationIndustry |

| #ConditionMonitoringAutomotiveindustry |

| #ConditionMonitoringSmelting |

| #ConditionMonitoringspinningindustries |

| #ConditionMonitoringCeramics |

| #ConditionMonitoringGlassIndustries |

| #ConditionMonitoringFoodindustry |

| #ConditionMonitoringFerroalloyindustries |

| #ConditionMonitoringSteelindustries |

| #ConditionMonitoringPalletization |

| #ConditionMonitoringMiningIndustry |

| #ConditionMonitoringSteelrollingindustries |

| #ConditionMonitoringPowerplantindustries |

| #ConditionMonitoringAluminumindustry |

| #ConditionMonitoringFAN |

| #ConditionMonitoringGasCooler |

| #ConditionMonitoringConveyor |

| #ConditionMonitoringCompressors |

| #ConditionMonitoringScrewCompressor |

| #ConditionMonitoringOilInjectedScrewCompressor |

| #ConditionMonitoringOilFreeScrewCompressors |

| #ConditionMonitoringProcessCompressor |

| #ConditionMonitoringRegenerationCompressors |

| #ConditionMonitoringReciprocatingCompressor |

| #ConditionMonitoringRotaryKiln |

| #ConditionMonitoringGearbox |

| #ConditionMonitoringPelletizingGearbox |

| #ConditionMonitoringRollingGearboxes |

| #ConditionMonitoringMixer |

| #ConditionMonitoringBearings |

| #ConditionMonitoringRollingBearings |

| #ConditionMonitoringJournalBearing |

| #Petroleum |

| #ReverseOsmosisPump |

| #HPPump |

| #Waterpumpingandtreatment |

| #OrbitTechnique |

| #BearingDamageVibrationAnalysis |

| #OrbitAnalysis |

| #TimeSignalAnalysis |

| #OperativeDeflectionShape |

| #FailureRootCauseanalysis |

| #PhaseAnalysis |

| #waterpurification |

| #Condensation |

| #OperatingDeflectionMode |

| #OperatingDeflectionShape |

| #ODS |

| #OMA |

| #TurboMachine |

| #Turbomachinery |

| #Turbine |

| #ReverseOsmosisTurbine |

| #ShaftCenterLine |

| #UltrasonicInspection |

| #VibrationAnalysisServices |

| #ShaftAlignmentService |

| #BalanceServices |

| #InsituBalanceService |

| #DynamicBalancingService |

| #FlexibleRotorBalancing |

| #ConditionMonitoringServices |

| #Thermography |

| #ThermographyInspection |

| #ThermographyService |

| #ShockPulseMeasuringServices |

| #ShockPulseHDServices |

| #AlignmentServices |

| #Diamond |

| #ISO184367CourseBased |

| #VibrationCourse |

| #ImplementationConditionMonitoringprogramCourses |

| #VibrationAnalysisCourses |

| #BearingVibrationCourse |

| #CompressorDamageVibrationAnalysis |

| #GearboxDamageVibrationAnalysis |

| #PhaseAnalysisCourse |

| #TimeSignalAnalysisCourse |

| #TurbomachineryCourse |

| #VibrationAnalysisCATIIMobiusISO18436-2 |

| #VibrationAnalysisCATIIIMobiusISO18436-2 |

| #VibrationAnalysisCATIMobiusISO18436-2 |

| #DesignConditionMonitoringprogramCourses |

| #TrainingCourses |

| #AdvancedVibrationsBasedOnACaseStudy |

| #ShaftAlignmentCource |

| #Pelletizingdiscs |

| #RotordynamicCourse |

| #Screen |

| #SagMill |

| #protectionsystems |

| #Bently3500 |

| #VM600protectionsystems |

| #NEC |

| #VMI |

| #Industry |

| #Revitalization |

| #Fiber |

| #packagin |

| #PetroleumRefineries |

| #Automotiveindustry |

| #Smelting |

| #spinning |

| #Ceramics |

| #GlassIndustries |

| #Foodindustry |

| #Ferroalloyindustries |

| #Palletization |

| #Mining |

| #Steelrollingindustries |

| #Powerplantindustries |

| #Aluminumindustry |

| #CementIndustry |

| #Falcon |

| #FLIR |

| #FAN |

| #GasCooler |

| #Steel |

| #CondmasterRuby |

| #Conveyor |

| #Compresspr |

| #ScrewCompressors |

| #OilInjectedScrewCompressor |

| #OilFreeScrewCompressors |

| #ProcessCompressor |

| #RegenerationCompressors |

| #ReciprocatingCompressor |

| #RotaryKiln |

| #Gearbox |

| #PelletizingGearbox |

| #RollingGearbox |

| #Matlab |

| #Maintenance |

| #AuthorizedMobiusPartner |

| #AuthorizedMobiusInstitutePartner |

| #SCL |

| #Rolling |

| #LaserAlignment |

| #VMICompany |

| #RollingBearing |

| #JournalBearing |

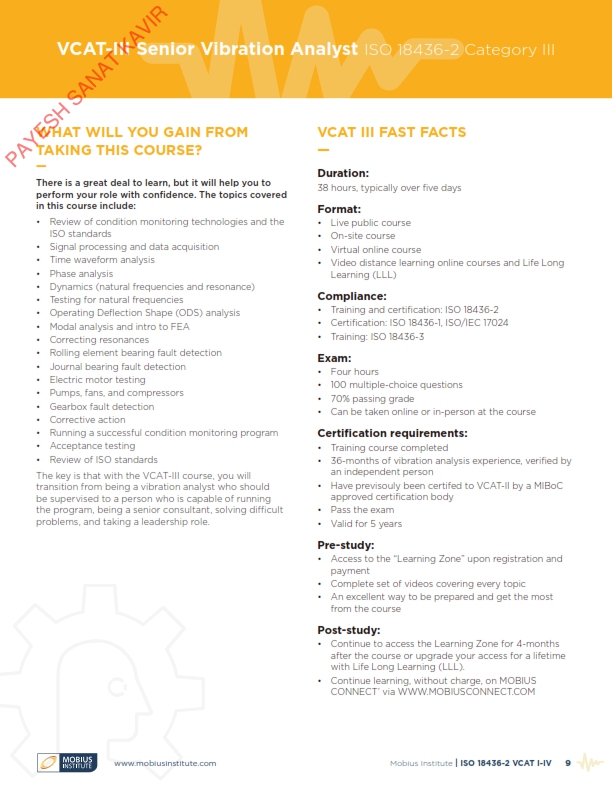

TOPICS COVERED – SENIOR ANALYST CATEGORY Ill :

| :Signal processing |

|---|

| Filters: Low pass, band pass, high pass, band stop |

| Sampling, aliasing, dynamic range |

| Signal-to-noise ratio |

| Resolution, Frnax, data collection time |

| Averaging: linear, overlap, peak hold, time synchronous |

| Windowing and leakage |

| Order tracking |

| Cross-channel measurements |

| Correlation and coherence |

| :Time waveform analysis |

|---|

| Collecting data — ensuring you have the correct setup |

| ?When should you use time waveform analysis |

| Diagnosing unbalance, misalignment, bent shaft, eccentricity, cocked bearing,resonance, looseness, and other conditions |

| :phase analysis |

|---|

| Collecting data |

| Bubble diagrams |

| Diagnosing unbalance, misalignment, bent shaft, eccentricity, cocked bearing, resonance, looseness, and other conditions |

| :Dynamics (natural frequencies and resonance) |

|---|

| Natural frequencies and resonances |

| Mass, stiffness, and damping |

| SDOF and MDOF |

| :Testing for natural frequencies |

|---|

| Run-up coast down tests |

| Bode plots and Nyquist (polar) plots |

| Impact and bump tests |

| :Operating Deflection Shape (ODS) analysis |

|---|

| ?Can we prove the existence of a natural frequency |

| Visualizing vibration |

| Setting up the job |

| Collecting phase readings correctly |

| Interpreting the deflection shape |

| Using Motion Amplification |

| :Modal analysis and intro to FEA |

|---|

| ?How does modal analysis differ from ODS |

| How does Finite Element Analysis (FEA) differ from modal analysis |

| A quick review of the modal testing process |

| :Correcting resonances |

|---|

| The effect of mass and stiffness |

| Beware of nodal points |

| Adding damping |

| A ‘trial and error’ approach |

| A ‘scientific’ approach |

| Isolation |

| Tuned absorbers and tuned mass dampers |

| :Rolling element bearing fault detection |

|---|

| ?Why do bearings fail |

| Cocked bearing, sliding on the shaft or inside the housing, looseness |

| EDM and DC motors and VFDs |

| Bearing frequencies and what to do when you don’t have all the details |

| The four stages of bearing degradation |

| Ultrasound |

| High-frequency detection techniques |

| Shock pulse, Spike Energy, peak Vue, and other techniques |

| Demodulation/enveloping |

| Selecting the correct filter settings |

| Spectrum analysis |

| Time waveform analysis |

| Low-speed bearings |

| :Journal bearing fault detection |

|---|

| ?What are journal bearings |

| Measuring displacement |

| Introduction to orbit plots |

| Using your analyzer to acquire orbit plots |

| Introduction to centerline diagrams |

| Eccentricity ratio |

| Glitch removal |

| How the orbit changes with pre-load, unbalance, misalignment, instabilities, oil whir and whip |

| :Electric motor testing |

|---|

| ?How do motors work |

| Diagnosing a range of fault conditions: eccentric rotor, eccentric stator, soft foot, phasing, broken rotor bars, rotor bar, and stator slot pass frequencies |

| Motor current analysis |

| :pumps, fans, and compressors |

|---|

| Unique fault conditions |

| Flow turbulence, recirculation, cavitation |

| :Gearbox fault detection |

|---|

| Spectrum analysis versus time waveform analysis |

| Wear particle analysis |

| Gearmesh, gear assembly phase frequency (and common factors) |

| Tooth load, broken teeth, gear eccentricity and misalignment, backlash and more |

| :Corrective action |

|---|

| General maintenance repair activities |

| Review of the balancing process and ISO balance grades |

| Review of shaft alignment procedures |

| :Running a successful condition monitoring program |

|---|

| Defining the program |

| Setting baselines |

| Setting alarms: band, envelope/mask, statistical |

| Setting goals and expectations (avoiding common problems) |

| Report generation |

| Reporting success stories |

| Acceptance testing |

|---|

| Review of ISO standards |

|---|

| BallMill |

| VibrationAnalysisCATI |

| VibrationAnalysisCATII |

| VibrationAnalysisCATIII |

| VibrationAnalysisCATIV |

| ExperimentalModalAnalysis |

| OperationalModalAnalysis |

| SPM |

| ISO184362 |

| ElectroFAN |

| MixerElectroGearbox |

| ElectroMotor |

| Emerald |

| EMA |

| Blower |

| BentyNavada |

| Bearing |

| Refineries |

| PayeshSanatKavirInstitute |

| ConditionMonitoringWatertreatment |

| ConditionMonitoringSagMill |

| ConditionMonitoringBallMill |

| ConditionMonitoringBearing |

| BearingVibrationConditionMonitoring |

| ConditionMonitoringReverseOsmosis |

| ConditionMonitoringElectroFAN |

| ConditionMonitoringMixerGearbox |

| ConditionMonitoringElectroMotor |

| ConditionMonitoringBlower |

| ConditionMonitoringBentlyNevada |

| RollingBearingConditionMonitoring |

| JournalBearingConditionMonitoring |

| ConditionMonitoringRefineries |

| ConditionMonitoringPetroleum |

| ConditionMonitoringpump |

| ConditionMonitoringHPPump |

| ConditionMonitoringpumping |

| ConditionMonitoringwaterpurification |

| ConditionMonitoringTurbine |

| ConditionMonitoringPelletizingdiscs |

| ConditionMonitoringScreen |

| ConditionMonitoringprotectionsystems |

| ConditionMonitoringBently3500 |

| ConditionMonitoringVM600 |

| ConditionMonitoringCementIndustry |

| ConditionMonitoringIndustry |

| ConditionMonitoringRevitalization |

| ConditionMonitoringFiber |

| ConditionMonitoringpackagin |

| ConditionMonitoringCondensationIndustry |

| ConditionMonitoringAutomotiveindustry |

| ConditionMonitoringSmelting |

| ConditionMonitoringspinningindustries |

| ConditionMonitoringCeramics |

| ConditionMonitoringGlassIndustries |

| ConditionMonitoringFoodindustry |

| ConditionMonitoringFerroalloyindustries |

| ConditionMonitoringSteelindustries |

| ConditionMonitoringPalletization |

| ConditionMonitoringMiningIndustry |

| ConditionMonitoringSteelrollingindustries |

| ConditionMonitoringPowerplantindustries |

| ConditionMonitoringAluminumindustry |

| ConditionMonitoringFAN |

| ConditionMonitoringGasCooler |

| ConditionMonitoringConveyor |

| ConditionMonitoringCompressors |

| ConditionMonitoringScrewCompressor |

| ConditionMonitoringOilInjectedScrewCompressor |

| ConditionMonitoringOilFreeScrewCompressors |

| ConditionMonitoringProcessCompressor |

| ConditionMonitoringRegenerationCompressors |

| ConditionMonitoringReciprocatingCompressor |

| ConditionMonitoringRotaryKiln |

| ConditionMonitoringGearbox |

| ConditionMonitoringPelletizingGearbox |

| ConditionMonitoringRollingGearboxes |

| ConditionMonitoringMixer |

| ConditionMonitoringBearings |

| ConditionMonitoringRollingBearings |

| ConditionMonitoringJournalBearing |

| Petroleum |

| ReverseOsmosisPump |

| HPPump |

| Waterpumpingandtreatment |

| OrbitTechnique |

| BearingDamageVibrationAnalysis |

| OrbitAnalysis |

| TimeSignalAnalysis |

| OperativeDeflectionShape |

| FailureRootCauseanalysis |

| PhaseAnalysis |

| waterpurification |

| Condensation |

| OperatingDeflectionMode |

| OperatingDeflectionShape |

| ODS |

| OMA |

| TurboMachine |

| Turbomachinery |

| Turbine |

| ReverseOsmosisTurbine |

| ShaftCenterLine |

| UltrasonicInspection |

| VibrationAnalysisServices |

| ShaftAlignmentService |

| BalanceServices |

| InsituBalanceService |

| DynamicBalancingService |

| FlexibleRotorBalancing |

| ConditionMonitoringServices |

| Thermography |

| ThermographyInspection |

| ThermographyService |

| ShockPulseMeasuringServices |

| ShockPulseHDServices |

| AlignmentServices |

| Diamond |

| ISO184367CourseBased |

| VibrationCourse |

| ImplementationConditionMonitoringprogramCourses |

| VibrationAnalysisCourses |

| BearingVibrationCourse |

| CompressorDamageVibrationAnalysis |

| GearboxDamageVibrationAnalysis |

| PhaseAnalysisCourse |

| TimeSignalAnalysisCourse |

| TurbomachineryCourse |

| VibrationAnalysisCATIIMobiusISO18436-2 |

| VibrationAnalysisCATIIIMobiusISO18436-2 |

| VibrationAnalysisCATIMobiusISO18436-2 |

| DesignConditionMonitoringprogramCourses |

| TrainingCourses |

| AdvancedVibrationsBasedOnACaseStudy |

| ShaftAlignmentCource |

| Pelletizingdiscs |

| RotordynamicCourse |

| Screen |

| SagMill |

| protectionsystems |

| Bently3500 |

| VM600protectionsystems |

| NEC |

| VMI |

| Industry |

| Revitalization |

| Fiber |

| packagin |

| PetroleumRefineries |

| Automotiveindustry |

| Smelting |

| spinning |

| Ceramics |

| GlassIndustries |

| Foodindustry |

| Ferroalloyindustries |

| Palletization |

| Mining |

| Steelrollingindustries |

| Powerplantindustries |

| Aluminumindustry |

| CementIndustry |

| Falcon |

| FLIR |

| FAN |

| GasCooler |

| Steel |

| CondmasterRuby |

| Conveyor |

| Compresspr |

| ScrewCompressors |

| OilInjectedScrewCompressor |

| OilFreeScrewCompressors |

| ProcessCompressor |

| RegenerationCompressors |

| ReciprocatingCompressor |

| RotaryKiln |

| Gearbox |

| PelletizingGearbox |

| RollingGearbox |

| Matlab |

| Maintenance |

| AuthorizedMobiusPartner |

| AuthorizedMobiusInstitutePartner |

| SCL |

| Rolling |

| LaserAlignment |

| VMICompany |

| RollingBearing |

| JournalBearing |

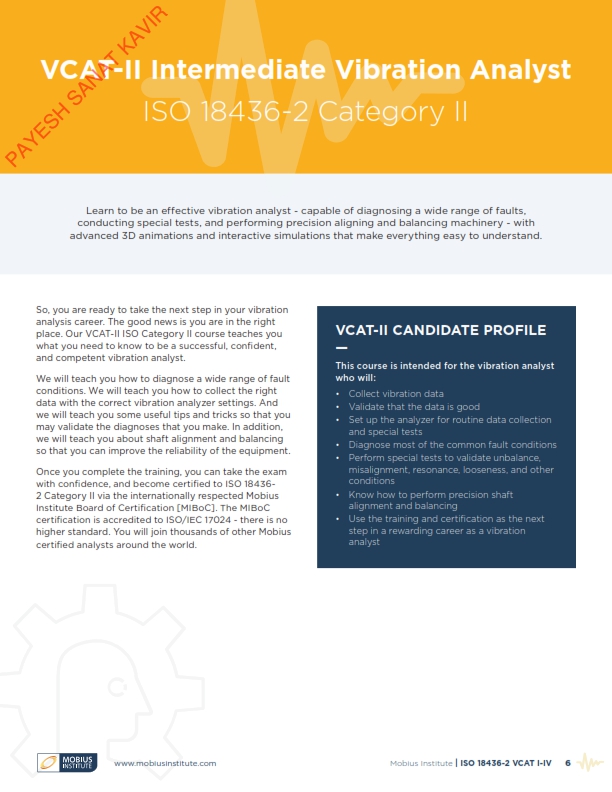

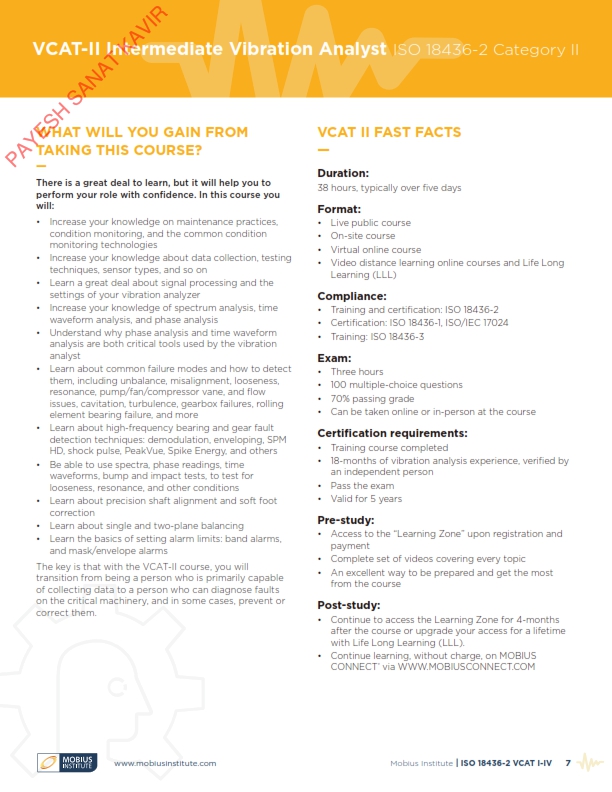

TOPICS COVERED – INTERMEDIATE ANALYST CATEGORY Il:

| Review of maintenance practices |

|---|

| Review of condition monitoring technologies |

|---|

| :Principles of vibration |

|---|

| Complete review of basics |

| Waveform, spectrum (FFT), phase and orbits |

| Understanding signals: modulation, beating, sum/difference |

| :Data acquisition |

|---|

| Transducer types: Non-contact displacement |

| :Proximity probes, velocity sensors, and accelerometers |

|---|

| Transducer selection |

| Transducer mounting and natural frequency |

| Measurement point selection |

| Following routes, and test planning |

| Common measurement errors |

| :Signal processing |

|---|

| Filters: Low pass, band pass, high pass, band stop |

| Sampling, aliasing, dynamic range |

| Resolution, Fmax, data collection time |

| Averaging: linear, overlap, peak hold, time synchronous |

| Windowing and leakage |

| :Vibration analysis |

|---|

| Spectrum analysis |

| Time waveform analysis (introduction) |

| Orbit analysis (introduction) |

| Phase analysis: bubble diagrams and ODS |

| Enveloping (demodulation), shock pulse, spike energy, PeakVue |

| :Fault analysis |

|---|

| Natural frequencies and resonances |

| Imbalance, eccentricity and bent shaft |

| Misalignment, cocked bearing and soft foot |

| Mechanical looseness |

| Rolling element bearing analysis |

| Analysis of induction motors |

| Analysis of gears |

| Analysis of belt-driven machines |

| Analysis of pumps, compressors, and fans |

| :Equipment testing and diagnostics |

|---|

| Impact testing and bump tests |

| Phase analysis |

| :Corrective action |

|---|

| General maintenance repair activities |

| Review of the balancing process |

| Review of shaft alignment procedures |

| :Running a successful condition monitoring program |

|---|

| Setting baselines |

| Setting alarms: band, envelope/mask, statistical |

| Setting goals and expectations (avoiding common problems) |

| Report generation |

| Reporting success stories |

| Acceptance testing |

|---|

| Review of ISO standards |

|---|

| Ball_Mill |

| Vibration_Analysis_CAT_I |

| Vibration_Analysis_CAT_II |

| Vibration_Analysis_CAT_III |

| Vibration_Analysis_CAT_IV |

| Experimental_Modal_Analysis |

| Operational_Modal_Analysis |

| SPM |

| ISO_18436_2 |

| Electro_FAN |

| Mixer_Electro_Gearbox |

| Electro_Motor |

| Emerald |

| EMA |

| Blower |

| Benty_Navada |

| Bearing |

| Refineries |

| Payesh_Sanat_Kavir_Institute |

| Condition_Monitoring_Water_treatment |

| Condition_Monitoring_Sag_Mill |

| Condition_Monitoring_Ball_Mill |

| Condition_Monitoring_Bearing |

| Bearing_Vibration_Condition_Monitoring |

| Condition_Monitoring_Reverse_Osmosis |

| Condition_Monitoring_Electro_FAN |

| Condition_Monitoring_Mixer_Gearbox |

| Condition_Monitoring_Electro_Motor |

| Condition_Monitoring_Blower |

| Condition_Monitoring_Bently_Nevada |

| Rolling_Bearing_Condition_Monitoring |

| Journal_Bearing_Condition_Monitoring |

| Condition_Monitoring_Refineries |

| Condition_Monitoring_Petroleum |

| Condition_Monitoring_pump |

| Condition_Monitoring_HP_Pump |

| Condition_Monitoring_pumping |

| Condition_Monitoring_water_purification |

| Condition_Monitoring_Turbine |

| Condition_Monitoring_Pelletizing_discs |

| Condition_Monitoring_Screen |

| Condition_Monitoring_protection_systems |

| Condition_Monitoring_Bently_3500 |

| Condition_Monitoring_VM600 |

| Condition_Monitoring_Cement_Industry |

| Condition_Monitoring_Industry |

| Condition_Monitoring_Revitalization |

| Condition_Monitoring_Fiber |

| Condition_Monitoring_packagin |

| Condition_Monitoring_Condensation_Industry |

| Condition_Monitoring_Automotive_industry |

| Condition_Monitoring_Smelting |

| Condition_Monitoring_spinning_industries |

| Condition_Monitoring_Ceramics |

| Condition_Monitoring_Glass_Industries |

| Condition_Monitoring_Food_industry |

| Condition_Monitoring_Ferroalloy_industries |

| Condition_Monitoring_Steel_industries |

| Condition_Monitoring_Palletization |

| Condition_Monitoring_Mining_Industry |

| Condition_Monitoring_Steel_rolling_industries |

| Condition_Monitoring_Power_plant_industries |

| Condition_Monitoring_Aluminum_industry |

| Condition_Monitoring_FAN |

| Condition_Monitoring_Gas_Cooler |

| Condition_Monitoring_Conveyor |

| Condition_Monitoring_Compressors |

| Condition_Monitoring_Screw_Compressor |

| Condition_Monitoring_Oil_Injected_Screw_Compressor |

| Condition_Monitoring_Oil_Free_Screw_Compressors |

| Condition_Monitoring_Process_Compressor |

| Condition_Monitoring_Regeneration_Compressors |

| Condition_Monitoring_Reciprocating_Compressor |

| Condition_Monitoring_Rotary_Kiln |

| Condition_Monitoring_Gearbox |

| Condition_Monitoring_Pelletizing_Gearbox |

| Condition_Monitoring_Rolling_Gearboxes |

| Condition_Monitoring_Mixer |

| Condition_Monitoring_Bearings |

| Condition_Monitoring_Rolling_Bearings |

| Condition_Monitoring_Journal_Bearing |

| Petroleum |

| Reverse_Osmosis_Pump |

| HP_Pump |

| Water_pumping_and_treatment |

| Orbit_Technique |

| Bearing_Damage_Vibration_Analysis |

| Orbit_Analysis |

| Time_Signal_Analysis |

| Operative_Deflection_Shape |

| Failure_Root_Cause_analysis |

| Phase_Analysis |

| water_purification |

| Condensation |

| Operating_Deflection_Mode |

| Operating_Deflection_Shape |

| ODS |

| OMA |

| TurboMachine |

| Turbomachinery |

| Turbine |

| Reverse_Osmosis_Turbine |

| Shaft_Center_Line |

| Ultrasonic_Inspection |

| Vibration_Analysis_Services |

| Shaft_Alignment_Service |

| Balance_Services |

| In_situ_Balance_Service |

| Dynamic_Balancing_Service |

| Flexible_Rotor_Balancing |

| Condition_Monitoring_Services |

| Thermography |

| Thermography_Inspection |

| Thermography_Service |

| Shock_Pulse_Measuring_Services |

| Shock_Pulse_HD_Services |

| Alignment_Services |

| Diamond |

| ISO_18436_7_Course_Based |

| Vibration_Course |

| Implementation_Condition_Monitoring_program_Courses |

| Vibration_Analysis_Courses |

| Bearing_Vibration_Course |

| Compressor_Damage_Vibration_Analysis |

| Gearbox_Damage_Vibration_Analysis |

| Phase_Analysis_Course |

| Time_Signal_Analysis_Course |

| Turbomachinery_Course |

| Vibration_Analysis_CAT_II_Mobius_ISO_18436-2 |

| Vibration_Analysis_CAT_III_Mobius_ISO_18436-2 |

| Vibration_Analysis_CAT_I_Mobius_ISO_18436-2 |

| Design_Condition_Monitoring_program_Courses |

| Training_Courses |

| Advanced_Vibrations_Based_On_A_Case_Study |

| Shaft_Alignment_Cource |

| Pelletizing_discs |

| Rotordynamic_Course |

| Screen |

| Sag_Mill |

| protection_systems |

| Bently_3500 |

| VM600_protection_systems |

| NEC |

| VMI |

| Industry |

| Revitalization |

| Fiber |

| packagin |

| Petroleum_Refineries |

| Automotive_industry |

| Smelting |

| spinning |

| Ceramics |

| Glass_Industries |

| Food_industry |

| Ferroalloy_industries |

| Palletization |

| Mining |

| Steel_rolling_industries |

| Power_plant_industries |

| Aluminum_industry |

| Cement_Industry |

| Falcon |

| FLIR |

| FAN |

| Gas_Cooler |

| Steel |

| Condmaster_Ruby |

| Conveyor |

| Compresspr |

| Screw_Compressors |

| Oil_Injected_Screw_Compressor |

| Oil_Free_Screw_Compressors |

| Process_Compressor |

| Regeneration_Compressors |

| Reciprocating_Compressor |

| Rotary_Kiln |

| Gearbox |

| Pelletizing_Gearbox |

| Rolling_Gearbox |

| Matlab |

| Maintenance |

| Authorized_Mobius_Partner |

| Authorized_Mobius_Institute_Partner |

| SCL |

| Rolling |

| Laser_Alignment |

| VMI_Company |

| Rolling_Bearing |

| Journal_Bearing |

TOPICS COVERED – JUNIOR ANALYST CATEGORY I:

| :Maintenance practices |

|---|

| Reactive, preventive, condition-based, proactive |

| How to decide |

| between them |

| :Condition monitoring |

|---|

| Why it works |

| Ultrasound, infrared, oil analysis, wear |

| particle analysis, and electric motor testing |

| :principles of vibration |

|---|

| Waveforms |

| Metrics: overall levels, RMS, P k, Pk-to-Peak, and crest factor |

| :Introduction to vibration measurement |

|---|

| Vibration sensors: displacement, velocity, acceleration |

| Vibration units |

| Mounting: where and how |

| Naming conventions |

| Repeatability and quality |

| Vibration axes: V, H, A, R, and T |

| ?What are “routes” and how do you create them |

| Detecting and avoiding poor data |

| An introduction to the time waveform |

|---|

| :An introduction to the spectrum |

|---|

| An introduction to forcing frequencies |

| A brief introduction to phase |

|---|

| :Signal processing (just the absolute basics) |

|---|

| A quick tour of your analyzer settings |

| Fmax |

| Resolution |

| Spectral averaging |

| :Vibration analysis |

|---|

| The spectrum analysis process |

| What is resonance — a quick introduction |

|---|

| :Diagnosing common fault conditions |

|---|

| Unbalance |

| Misalignment |

| Rolling element bearing failure |

| Looseness |

| Resonance |

| Setting alarm limits |

|---|

Rolling Bearings are vital components in various industries and ensure accurate and smooth rotation of equipment.

Various defects and failures can happen to them, which prevent their efficiency and proper functioning.

Bearing failure creates many parallel and simultaneous patterns. Full knowledge of these patterns helps us to diagnose their failure with sufficient confidence even without “having enough information about the bearing number”.

An example of vibration techniques for detecting bearing defects that we can use to correctly diagnose the failure and estimate its severity:

A- Frequency spectrum Symptom of Vibration velocity spectrum)

B-1 Vibration acceleration spectrum: Frequency spectrum Symptom

B-2 Vibration acceleration spectrum: Noise floor

C- Pattern of time signal Vibration acceleration

D- Frequency spectrum Symptom of acceleration envelope

E- Evaluation of the value or changes (trend) of the values of different parameters

Each parameter gives us a value that hopefully represents the health or failure of the bearing. Certainly, if this method (method E) is highly reliable, it will greatly reduce our work in reducing analyzes (methods A to D)

To use a parameter correctly, it is necessary to know exactly how it is calculated, because only in this case we will be able to have a correct understanding of its accuracy and the reason for its changes under different conditions.

In various industries, we have seen that the incorrect use of parameters has led to premature replacement of healthy bearings or even jamming of the bearing without warning.

For this reason, in the training course “BEARING DAMAGE VIBRATION ANALYSIS”, while testing several different failures, we examine the effect of failure severity and rotation speed on the values of different parameters.

We also examine the theoretical concepts related to these parameters and the conditions under which these parameters have errors.

Also, in order to increase accuracy, we will examine how to “simultaneously use” the “above techniques (A to E)” so that we can ensure the presence of failure and the severity of failure growth with sufficient confidence.

Today, different equipments offer different parameters according to their available signal processing and sensors:

In this brief article, we review some of these parameters:

BC- Skew- BCU -HDM- dBM- SFx-Spike Energy- Peak value-Crest Factor- Envelope Parameter

dBM parameter of the SPM Sock Pulse Method: Is calculated from the statistical analysis of the detected signals at very high frequencies.

HDM parameter: It is an improved method of dBM parameter.

BC parameter: It is the RMS value of acceleration signal with high-pass filter.

BCU parameter or Bearing Condition Unit: It is a parameter that expresses the condition of the high frequency vibration range.

The parameters extracted from the envelope signal: These parameters are depend on the demodulated acceleration signal in the considered frequency band. Considering that the signal is manipulated in the envelope process, the obtained units are not standard and different equipment use different units to express the value of the envelope signal. Such as: eu, Hdrp, gE, …

Kurt or Kutosis parameter: Kurtosis; the amount of transients in the vibration signal “tailedness” of the probability distribution of random variable.

Crest Factor parameter or sharpness index: It shows the ratio of the peak value to the RMS value. To diagnose bearing failure, this parameter is often checked in the acceleration unit.

RMS parameter: shows the RMS value of the signal. To detect bearing failure, this parameter is often checked in the acceleration unit.

Some of the out cases ostudy whose will be analyzed individually by candidates

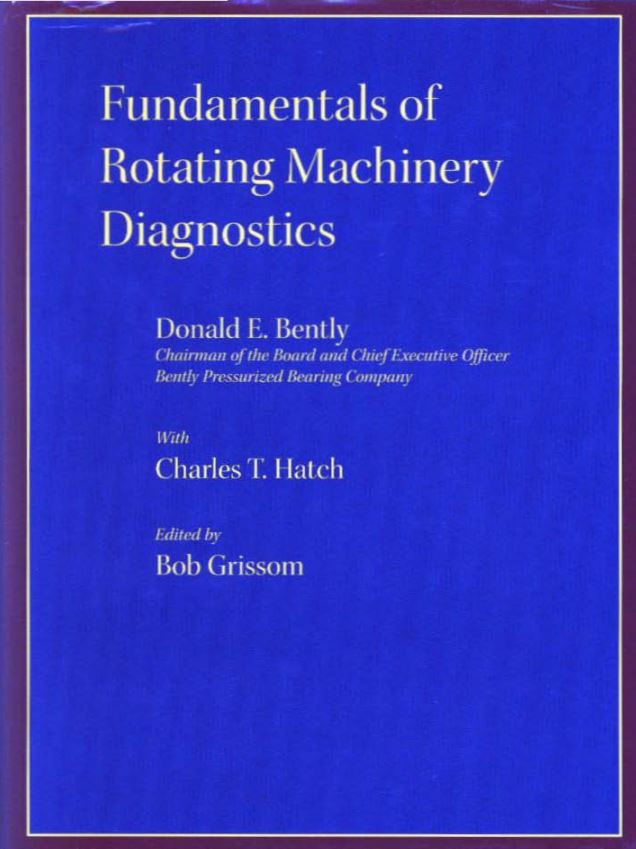

This reference and its contents are one of the best references for turbomachinery courses

Table of Content

Vibration

| The Basic Vibration Signal | |

| Frequency | |

| Amplitude | |

| Displacement, Velocity, and Acceleration | |

| The Vibration of Machines | |

| Rotation and Precession | |

| Free Vibration | |

| Forced Vibration | |

| Resonance | |

| Self-Excited Vibration | |

| Summary |

Phase

| What is Phase | |

| Why Is Phase Important | |

| The Keyphasor Event | |

| Phase Measurement | |

| Absolute Phase | |

| Relative Phase | |

| Differential Phase | |

| Summary |

Vibration Vectors

| Unfiltered Vibration | |

| Filtering and the Vibration Vector | |

| Working with Vibration Vectors | |

| The Slow Roll Vector | |

| Summary |

Timebase Plots

| The Structure of a Timebase Plot | |

| The Keyphasor Mark | |

| Compensation of Timebase Plots | |

| Information Contained in the Timebase Plot | |

| Summary |

The Orbit

| The Construction of the Orbit | |

| The Keyphasor Mark | |

| Compensation of Orbits | |

| Information Contained in the Orbit | |

| The Orbit/Timebase Plot | |

| Summary |

Average Shaft Centerline Plots

| The Construction of the Average Shaft Centerline Plot | |

| Information Contained in the Average Shaft Centerline Plot | |

| The Complete Picture: Orbit Plus Average Shaft Centerline Position | |

| Summary |

Polar, Bode, and APHT Plots

| The Structure of Polar and Bode Plots | |

| Slow Roll Compensation | |

| Information Contained in Polar and Bode Plots | |

| APHT Plots | |

| Acceptance Region Plots | |

| Summary | |

| References |

Half and Full Spectrum Plots

| The Half Spectrum Plot | |

| Technical Issues | |

| The Full Spectrum | |

| Spectrum Cascade Plots | |

| Spectrum Waterfall Plots | |

| Summary |

The Rotor System Model

| Introduction to Modeling | |

| Assumptions | |

| The Coordinate System and Position Vector | |

| Lambda (A): A Model of Fluid Circulation | |

| Fluid-film Bearing Forces and Stiffnesses | |

| Other Sources of Spring Stiffness | |

| The Damping Force | |

| The Perturbation Force | |

| The Free Body Diagram | |

| The Equation of Motion | |

| Solution of the Equation of Motion | |

| Nonsynchronous Dynamic Stiffness | |

| Amplitude and Phase of the Vibration Response | |

| The Attitude Angle: Rotor Response to a Static Radial Load | |

| Synchronous Rotor Response | |

| Synchronous Dynamic Stiffness | |

| Predicted Rotor Vibration | |

| Nonlinearities | |

| The Benefits and Limitations of the Simple Model | |

| Extending the Simple Model | |

| Summary | |

| References |

Dynamic Stiffness and Rotor Behavior

| What Is Dynamic Stiffness | |

| Rotor Parameters and Dynamic Stiffness | |

| Synchronous Rotor Behavior | |

| Synchronous Behavior Below Resonance | |

| Synchronous Behavior At The Balance Resonance | |

| How Changes In Dynamic Stiffness Affect Vibration | |

| Summary |

Modes of Vibration

| Mode Shapes | |

| Forced Mode Shapes and Multimode Response | |

| Modal Parameters | |

| The Measurement of Mode Shape | |

| Mode Identification Probes | |

| Summary |

Anisotropic Stiffness

| Anisotropic Stiffness | |

| Split Resonances | |

| Measured Rotor Behavior and Anisotropic Stiffness | |

| Probe Mounting Orientation and Measured Response | |

| Virtual Probe Rotation | |

| Forward and Reverse Vectors | |

| Summary | |

| References |

Rotor Stability Analysis: The Root Locus

| What is Stability | |

| Stability and Dynamic Stiffness | |

| Stability Analysis | |

| State-Space Formulation of the Eigenvalue Problem | |

| The Root Locus Plot | |

| The Root Locus and Amplification Factors | |

| Parameter Variation and the Root Locus | |

| The Root Locus of Anisotropic and Multimode Systems | |

| The Root Locus and the Logarithmic Decrement | |

| The Root Locus and the Campbell Diagram | |

| Root Locus Analysis of Machine Stability Problems | |

| Summary | |

| References |

Torsional and Axial Vibration

| The Torsional View of the Rotor | |

| Static and Dynamic Torsional Response | |

| Torsional/Radial Cross Coupling | |

| Torsional Vibration Measurement | |

| Axial Vibration | |

| Summary | |

| References |

Basic Balancing of Rotor Systems

| Unbalance and Rotor Response | |

| Vibration Transducers And Balancing | |

| Balancing Methodology | |

| Locating the Heavy Spot Using a Polar Plot | |

| Using Polar Plots Of Velocity and Acceleration Data | |

| Selecting the Calibration Weight | |

| Relating Balance Ring Location To Polar Plot Location | |

| Single Plane Balancing With Calibration Weights | |

| Weight Splitting | |

| The Influence Vector | |

| The Influence Vector And Dynamic Stiffness | |

| Multiple Modes And Multiplane Balancing | |

| Multiplane Balancing With Influence Vectors | |

| How Balancing Can Go Wrong | |

| Summary | |

| References |

Malfunctions

Introduction to Malfunctions

| What is a Malfunction | |

| Detection of Malfunctions |

Unbalance

| Rotor System Vibration Due To Unbalance | |

| Stress and Damage | |

| Other Things That Can Look Like Unbalance | |

| Runout | |

| Rotor Bow | |

| Electrical Noise in the Transducer System | |

| Coupling Problems | |

| Shaft Crack | |

| Loose Part or Debris | |

| Rotor Dynamic Effects of Rotor Bow | |

| Thermal Bow During Operation | |

| Diagnosing Rotor Bow | |

| Removing Rotor Bow | |

| Summary | |

| References |

High Radial Loads and Misalignment

| Static Radial Loads | |

| What Is Misalignment | |

| Temperature Changes and Alignment | |

| Causes of Misalignment | |

| Symptoms of High Radial Load and Misalignment | |

| Bearing Temperature | |

| Vibration Changes | |

| Stresses and Wear | |

| Abnormal Average Shaft Centerline Position | |

| Orbit Shape | |

| Rub | |

| Fluid-induced Instability | |

| Summary |

Rub and Looseness

| Rub and Looseness | |

| Partial Radial Rub | |

| Full Annular Rub | |

| Rub-Induced Forces and Spring Stiffness Changes | |

| Rub and Steady State 1X Vibration | |

| Rub and IX Vibration During Resonance | |

| Subsynchronous Vibration | |

| Symptoms of Rub | |

| Other Malfunctions with Similar Symptom | |

| Summary |

Fluid-Induced Instability

| The Cause of Fluid-Induced Instability | |

| Modes of Instability: Whirl and Whip | |

| Symptoms of Fluid-induced Instability | |

| Other Malfunctions That Can Produce Similar Symptoms | |

| Locating the Source of Instability | |

| Eliminating Fluid-Induced Instability | |

| Summary |

Externally Pressurized Bearings and Machinery Diagnostics

| Types of Bearings | |

| Internally Pressurized Fluid-Film Bearings | |

| Externally Pressurized Fluid-Film Bearings | |

| Stiffness and Modal Damping in Fluid-Film Bearings | |

| Variable Stiffness in Internally Pressurized Bearings | |

| Variable Stiffness in Externally Pressurized Bearings | |

| Rotor Dynamic Implication of Variable Stiffness Bearings | |

| Diagnostic Implications of Variable Stiffness Bearings | |

| Summary | |

| References |

Shaft Cracks

| Crack Initiation, Growth, and Fracture | |

| Reduction of Shaft Stiffness Due To a Crack | |

| Shaft Asymmetry and 2X Vibration | |

| The First Rule of Crack Detection (1X) | |

| The Second Rule of Crack Detection (2X) | |

| Other Malfunctions That Produce IX Vibration Changes | |

| Other Malfunctions That Produce 2X Vibration | |

| Design and Operating Recommendations | |

| Monitoring Recommendations | |

| Summary |

Appendix

| A1 Phase Measurement Conventions The Instrumentation Convention The Mathematical Convention Converting Between The Two Conventions Phase on Bode and APHT Plots | |

| A2 Filtered Orbit and Timebase Synthesis Timebase Synthesis Orbit Synthesis | |

| A3 The Origin Of the Tangential Stiffness Term Modeling the Pressure Wedge Transformation to Stationary Coordinates Reference | |

| A4 SAF Calculation Peak Ratio Method Phase Slope Method Polar Plot Method | |

| A5 Vector Transforms Virtual Probe Rotation The Forward and Reverse Transform and Full Spectrum References | |

| A7 Units of Measurement Metric/US Customary Unit Conversions Unit Prefixes Unit Abbreviations Force, Weight. and Mass in the US Customary System | |

| AS Nomenclature Upper case Homan Lower case Roman Upper case Greek Lower case Greek |