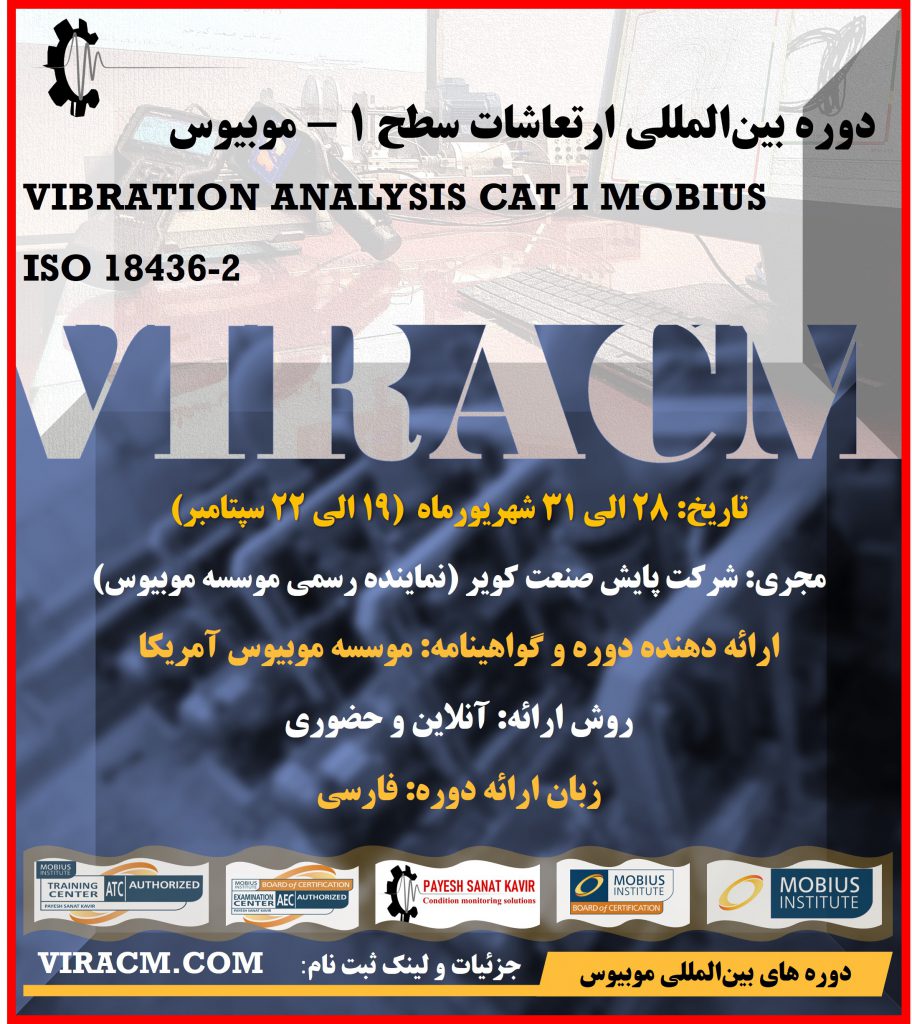

Register Link for PAYESH SANAT KAVIR Courses

ثبت نام در دورههای پایش صنعت کویر

Training with testing AND Analysis

تقویم آموزشی دوره های داخلی

Payesh Sanat Kavir Course Calendar

Register Link for PAYESH SANAT KAVIR Courses

ثبت نام در دورههای پایش صنعت کویر

Training with testing AND Analysis

تقویم آموزشی دوره های داخلی

Payesh Sanat Kavir Course Calendar

TOPICS COVERED – SENIOR ANALYST CATEGORY Ill :

| :Signal processing |

|---|

| Filters: Low pass, band pass, high pass, band stop |

| Sampling, aliasing, dynamic range |

| Signal-to-noise ratio |

| Resolution, Frnax, data collection time |

| Averaging: linear, overlap, peak hold, time synchronous |

| Windowing and leakage |

| Order tracking |

| Cross-channel measurements |

| Correlation and coherence |

| :Time waveform analysis |

|---|

| Collecting data — ensuring you have the correct setup |

| ?When should you use time waveform analysis |

| Diagnosing unbalance, misalignment, bent shaft, eccentricity, cocked bearing,resonance, looseness, and other conditions |

| :phase analysis |

|---|

| Collecting data |

| Bubble diagrams |

| Diagnosing unbalance, misalignment, bent shaft, eccentricity, cocked bearing, resonance, looseness, and other conditions |

| :Dynamics (natural frequencies and resonance) |

|---|

| Natural frequencies and resonances |

| Mass, stiffness, and damping |

| SDOF and MDOF |

| :Testing for natural frequencies |

|---|

| Run-up coast down tests |

| Bode plots and Nyquist (polar) plots |

| Impact and bump tests |

| :Operating Deflection Shape (ODS) analysis |

|---|

| ?Can we prove the existence of a natural frequency |

| Visualizing vibration |

| Setting up the job |

| Collecting phase readings correctly |

| Interpreting the deflection shape |

| Using Motion Amplification |

| :Modal analysis and intro to FEA |

|---|

| ?How does modal analysis differ from ODS |

| How does Finite Element Analysis (FEA) differ from modal analysis |

| A quick review of the modal testing process |

| :Correcting resonances |

|---|

| The effect of mass and stiffness |

| Beware of nodal points |

| Adding damping |

| A ‘trial and error’ approach |

| A ‘scientific’ approach |

| Isolation |

| Tuned absorbers and tuned mass dampers |

| :Rolling element bearing fault detection |

|---|

| ?Why do bearings fail |

| Cocked bearing, sliding on the shaft or inside the housing, looseness |

| EDM and DC motors and VFDs |

| Bearing frequencies and what to do when you don’t have all the details |

| The four stages of bearing degradation |

| Ultrasound |

| High-frequency detection techniques |

| Shock pulse, Spike Energy, peak Vue, and other techniques |

| Demodulation/enveloping |

| Selecting the correct filter settings |

| Spectrum analysis |

| Time waveform analysis |

| Low-speed bearings |

| :Journal bearing fault detection |

|---|

| ?What are journal bearings |

| Measuring displacement |

| Introduction to orbit plots |

| Using your analyzer to acquire orbit plots |

| Introduction to centerline diagrams |

| Eccentricity ratio |

| Glitch removal |

| How the orbit changes with pre-load, unbalance, misalignment, instabilities, oil whir and whip |

| :Electric motor testing |

|---|

| ?How do motors work |

| Diagnosing a range of fault conditions: eccentric rotor, eccentric stator, soft foot, phasing, broken rotor bars, rotor bar, and stator slot pass frequencies |

| Motor current analysis |

| :pumps, fans, and compressors |

|---|

| Unique fault conditions |

| Flow turbulence, recirculation, cavitation |

| :Gearbox fault detection |

|---|

| Spectrum analysis versus time waveform analysis |

| Wear particle analysis |

| Gearmesh, gear assembly phase frequency (and common factors) |

| Tooth load, broken teeth, gear eccentricity and misalignment, backlash and more |

| :Corrective action |

|---|

| General maintenance repair activities |

| Review of the balancing process and ISO balance grades |

| Review of shaft alignment procedures |

| :Running a successful condition monitoring program |

|---|

| Defining the program |

| Setting baselines |

| Setting alarms: band, envelope/mask, statistical |

| Setting goals and expectations (avoiding common problems) |

| Report generation |

| Reporting success stories |

| Acceptance testing |

|---|

| Review of ISO standards |

|---|

| BallMill |

| VibrationAnalysisCATI |

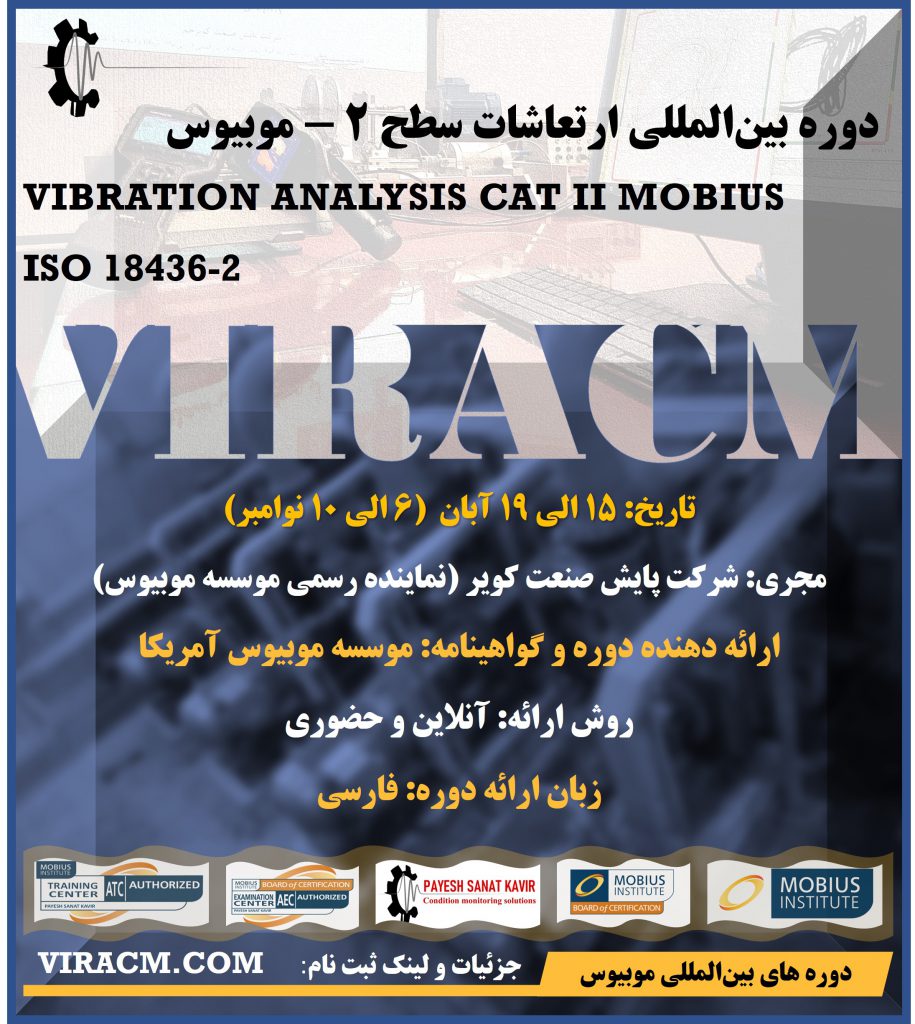

| VibrationAnalysisCATII |

| VibrationAnalysisCATIII |

| VibrationAnalysisCATIV |

| ExperimentalModalAnalysis |

| OperationalModalAnalysis |

| SPM |

| ISO184362 |

| ElectroFAN |

| MixerElectroGearbox |

| ElectroMotor |

| Emerald |

| EMA |

| Blower |

| BentyNavada |

| Bearing |

| Refineries |

| PayeshSanatKavirInstitute |

| ConditionMonitoringWatertreatment |

| ConditionMonitoringSagMill |

| ConditionMonitoringBallMill |

| ConditionMonitoringBearing |

| BearingVibrationConditionMonitoring |

| ConditionMonitoringReverseOsmosis |

| ConditionMonitoringElectroFAN |

| ConditionMonitoringMixerGearbox |

| ConditionMonitoringElectroMotor |

| ConditionMonitoringBlower |

| ConditionMonitoringBentlyNevada |

| RollingBearingConditionMonitoring |

| JournalBearingConditionMonitoring |

| ConditionMonitoringRefineries |

| ConditionMonitoringPetroleum |

| ConditionMonitoringpump |

| ConditionMonitoringHPPump |

| ConditionMonitoringpumping |

| ConditionMonitoringwaterpurification |

| ConditionMonitoringTurbine |

| ConditionMonitoringPelletizingdiscs |

| ConditionMonitoringScreen |

| ConditionMonitoringprotectionsystems |

| ConditionMonitoringBently3500 |

| ConditionMonitoringVM600 |

| ConditionMonitoringCementIndustry |

| ConditionMonitoringIndustry |

| ConditionMonitoringRevitalization |

| ConditionMonitoringFiber |

| ConditionMonitoringpackagin |

| ConditionMonitoringCondensationIndustry |

| ConditionMonitoringAutomotiveindustry |

| ConditionMonitoringSmelting |

| ConditionMonitoringspinningindustries |

| ConditionMonitoringCeramics |

| ConditionMonitoringGlassIndustries |

| ConditionMonitoringFoodindustry |

| ConditionMonitoringFerroalloyindustries |

| ConditionMonitoringSteelindustries |

| ConditionMonitoringPalletization |

| ConditionMonitoringMiningIndustry |

| ConditionMonitoringSteelrollingindustries |

| ConditionMonitoringPowerplantindustries |

| ConditionMonitoringAluminumindustry |

| ConditionMonitoringFAN |

| ConditionMonitoringGasCooler |

| ConditionMonitoringConveyor |

| ConditionMonitoringCompressors |

| ConditionMonitoringScrewCompressor |

| ConditionMonitoringOilInjectedScrewCompressor |

| ConditionMonitoringOilFreeScrewCompressors |

| ConditionMonitoringProcessCompressor |

| ConditionMonitoringRegenerationCompressors |

| ConditionMonitoringReciprocatingCompressor |

| ConditionMonitoringRotaryKiln |

| ConditionMonitoringGearbox |

| ConditionMonitoringPelletizingGearbox |

| ConditionMonitoringRollingGearboxes |

| ConditionMonitoringMixer |

| ConditionMonitoringBearings |

| ConditionMonitoringRollingBearings |

| ConditionMonitoringJournalBearing |

| Petroleum |

| ReverseOsmosisPump |

| HPPump |

| Waterpumpingandtreatment |

| OrbitTechnique |

| BearingDamageVibrationAnalysis |

| OrbitAnalysis |

| TimeSignalAnalysis |

| OperativeDeflectionShape |

| FailureRootCauseanalysis |

| PhaseAnalysis |

| waterpurification |

| Condensation |

| OperatingDeflectionMode |

| OperatingDeflectionShape |

| ODS |

| OMA |

| TurboMachine |

| Turbomachinery |

| Turbine |

| ReverseOsmosisTurbine |

| ShaftCenterLine |

| UltrasonicInspection |

| VibrationAnalysisServices |

| ShaftAlignmentService |

| BalanceServices |

| InsituBalanceService |

| DynamicBalancingService |

| FlexibleRotorBalancing |

| ConditionMonitoringServices |

| Thermography |

| ThermographyInspection |

| ThermographyService |

| ShockPulseMeasuringServices |

| ShockPulseHDServices |

| AlignmentServices |

| Diamond |

| ISO184367CourseBased |

| VibrationCourse |

| ImplementationConditionMonitoringprogramCourses |

| VibrationAnalysisCourses |

| BearingVibrationCourse |

| CompressorDamageVibrationAnalysis |

| GearboxDamageVibrationAnalysis |

| PhaseAnalysisCourse |

| TimeSignalAnalysisCourse |

| TurbomachineryCourse |

| VibrationAnalysisCATIIMobiusISO18436-2 |

| VibrationAnalysisCATIIIMobiusISO18436-2 |

| VibrationAnalysisCATIMobiusISO18436-2 |

| DesignConditionMonitoringprogramCourses |

| TrainingCourses |

| AdvancedVibrationsBasedOnACaseStudy |

| ShaftAlignmentCource |

| Pelletizingdiscs |

| RotordynamicCourse |

| Screen |

| SagMill |

| protectionsystems |

| Bently3500 |

| VM600protectionsystems |

| NEC |

| VMI |

| Industry |

| Revitalization |

| Fiber |

| packagin |

| PetroleumRefineries |

| Automotiveindustry |

| Smelting |

| spinning |

| Ceramics |

| GlassIndustries |

| Foodindustry |

| Ferroalloyindustries |

| Palletization |

| Mining |

| Steelrollingindustries |

| Powerplantindustries |

| Aluminumindustry |

| CementIndustry |

| Falcon |

| FLIR |

| FAN |

| GasCooler |

| Steel |

| CondmasterRuby |

| Conveyor |

| Compresspr |

| ScrewCompressors |

| OilInjectedScrewCompressor |

| OilFreeScrewCompressors |

| ProcessCompressor |

| RegenerationCompressors |

| ReciprocatingCompressor |

| RotaryKiln |

| Gearbox |

| PelletizingGearbox |

| RollingGearbox |

| Matlab |

| Maintenance |

| AuthorizedMobiusPartner |

| AuthorizedMobiusInstitutePartner |

| SCL |

| Rolling |

| LaserAlignment |

| VMICompany |

| RollingBearing |

| JournalBearing |

TOPICS COVERED – INTERMEDIATE ANALYST CATEGORY Il:

| Review of maintenance practices |

|---|

| Review of condition monitoring technologies |

|---|

| :Principles of vibration |

|---|

| Complete review of basics |

| Waveform, spectrum (FFT), phase and orbits |

| Understanding signals: modulation, beating, sum/difference |

| :Data acquisition |

|---|

| Transducer types: Non-contact displacement |

| :Proximity probes, velocity sensors, and accelerometers |

|---|

| Transducer selection |

| Transducer mounting and natural frequency |

| Measurement point selection |

| Following routes, and test planning |

| Common measurement errors |

| :Signal processing |

|---|

| Filters: Low pass, band pass, high pass, band stop |

| Sampling, aliasing, dynamic range |

| Resolution, Fmax, data collection time |

| Averaging: linear, overlap, peak hold, time synchronous |

| Windowing and leakage |

| :Vibration analysis |

|---|

| Spectrum analysis |

| Time waveform analysis (introduction) |

| Orbit analysis (introduction) |

| Phase analysis: bubble diagrams and ODS |

| Enveloping (demodulation), shock pulse, spike energy, PeakVue |

| :Fault analysis |

|---|

| Natural frequencies and resonances |

| Imbalance, eccentricity and bent shaft |

| Misalignment, cocked bearing and soft foot |

| Mechanical looseness |

| Rolling element bearing analysis |

| Analysis of induction motors |

| Analysis of gears |

| Analysis of belt-driven machines |

| Analysis of pumps, compressors, and fans |

| :Equipment testing and diagnostics |

|---|

| Impact testing and bump tests |

| Phase analysis |

| :Corrective action |

|---|

| General maintenance repair activities |

| Review of the balancing process |

| Review of shaft alignment procedures |

| :Running a successful condition monitoring program |

|---|

| Setting baselines |

| Setting alarms: band, envelope/mask, statistical |

| Setting goals and expectations (avoiding common problems) |

| Report generation |

| Reporting success stories |

| Acceptance testing |

|---|

| Review of ISO standards |

|---|

| Ball_Mill |

| Vibration_Analysis_CAT_I |

| Vibration_Analysis_CAT_II |

| Vibration_Analysis_CAT_III |

| Vibration_Analysis_CAT_IV |

| Experimental_Modal_Analysis |

| Operational_Modal_Analysis |

| SPM |

| ISO_18436_2 |

| Electro_FAN |

| Mixer_Electro_Gearbox |

| Electro_Motor |

| Emerald |

| EMA |

| Blower |

| Benty_Navada |

| Bearing |

| Refineries |

| Payesh_Sanat_Kavir_Institute |

| Condition_Monitoring_Water_treatment |

| Condition_Monitoring_Sag_Mill |

| Condition_Monitoring_Ball_Mill |

| Condition_Monitoring_Bearing |

| Bearing_Vibration_Condition_Monitoring |

| Condition_Monitoring_Reverse_Osmosis |

| Condition_Monitoring_Electro_FAN |

| Condition_Monitoring_Mixer_Gearbox |

| Condition_Monitoring_Electro_Motor |

| Condition_Monitoring_Blower |

| Condition_Monitoring_Bently_Nevada |

| Rolling_Bearing_Condition_Monitoring |

| Journal_Bearing_Condition_Monitoring |

| Condition_Monitoring_Refineries |

| Condition_Monitoring_Petroleum |

| Condition_Monitoring_pump |

| Condition_Monitoring_HP_Pump |

| Condition_Monitoring_pumping |

| Condition_Monitoring_water_purification |

| Condition_Monitoring_Turbine |

| Condition_Monitoring_Pelletizing_discs |

| Condition_Monitoring_Screen |

| Condition_Monitoring_protection_systems |

| Condition_Monitoring_Bently_3500 |

| Condition_Monitoring_VM600 |

| Condition_Monitoring_Cement_Industry |

| Condition_Monitoring_Industry |

| Condition_Monitoring_Revitalization |

| Condition_Monitoring_Fiber |

| Condition_Monitoring_packagin |

| Condition_Monitoring_Condensation_Industry |

| Condition_Monitoring_Automotive_industry |

| Condition_Monitoring_Smelting |

| Condition_Monitoring_spinning_industries |

| Condition_Monitoring_Ceramics |

| Condition_Monitoring_Glass_Industries |

| Condition_Monitoring_Food_industry |

| Condition_Monitoring_Ferroalloy_industries |

| Condition_Monitoring_Steel_industries |

| Condition_Monitoring_Palletization |

| Condition_Monitoring_Mining_Industry |

| Condition_Monitoring_Steel_rolling_industries |

| Condition_Monitoring_Power_plant_industries |

| Condition_Monitoring_Aluminum_industry |

| Condition_Monitoring_FAN |

| Condition_Monitoring_Gas_Cooler |

| Condition_Monitoring_Conveyor |

| Condition_Monitoring_Compressors |

| Condition_Monitoring_Screw_Compressor |

| Condition_Monitoring_Oil_Injected_Screw_Compressor |

| Condition_Monitoring_Oil_Free_Screw_Compressors |

| Condition_Monitoring_Process_Compressor |

| Condition_Monitoring_Regeneration_Compressors |

| Condition_Monitoring_Reciprocating_Compressor |

| Condition_Monitoring_Rotary_Kiln |

| Condition_Monitoring_Gearbox |

| Condition_Monitoring_Pelletizing_Gearbox |

| Condition_Monitoring_Rolling_Gearboxes |

| Condition_Monitoring_Mixer |

| Condition_Monitoring_Bearings |

| Condition_Monitoring_Rolling_Bearings |

| Condition_Monitoring_Journal_Bearing |

| Petroleum |

| Reverse_Osmosis_Pump |

| HP_Pump |

| Water_pumping_and_treatment |

| Orbit_Technique |

| Bearing_Damage_Vibration_Analysis |

| Orbit_Analysis |

| Time_Signal_Analysis |

| Operative_Deflection_Shape |

| Failure_Root_Cause_analysis |

| Phase_Analysis |

| water_purification |

| Condensation |

| Operating_Deflection_Mode |

| Operating_Deflection_Shape |

| ODS |

| OMA |

| TurboMachine |

| Turbomachinery |

| Turbine |

| Reverse_Osmosis_Turbine |

| Shaft_Center_Line |

| Ultrasonic_Inspection |

| Vibration_Analysis_Services |

| Shaft_Alignment_Service |

| Balance_Services |

| In_situ_Balance_Service |

| Dynamic_Balancing_Service |

| Flexible_Rotor_Balancing |

| Condition_Monitoring_Services |

| Thermography |

| Thermography_Inspection |

| Thermography_Service |

| Shock_Pulse_Measuring_Services |

| Shock_Pulse_HD_Services |

| Alignment_Services |

| Diamond |

| ISO_18436_7_Course_Based |

| Vibration_Course |

| Implementation_Condition_Monitoring_program_Courses |

| Vibration_Analysis_Courses |

| Bearing_Vibration_Course |

| Compressor_Damage_Vibration_Analysis |

| Gearbox_Damage_Vibration_Analysis |

| Phase_Analysis_Course |

| Time_Signal_Analysis_Course |

| Turbomachinery_Course |

| Vibration_Analysis_CAT_II_Mobius_ISO_18436-2 |

| Vibration_Analysis_CAT_III_Mobius_ISO_18436-2 |

| Vibration_Analysis_CAT_I_Mobius_ISO_18436-2 |

| Design_Condition_Monitoring_program_Courses |

| Training_Courses |

| Advanced_Vibrations_Based_On_A_Case_Study |

| Shaft_Alignment_Cource |

| Pelletizing_discs |

| Rotordynamic_Course |

| Screen |

| Sag_Mill |

| protection_systems |

| Bently_3500 |

| VM600_protection_systems |

| NEC |

| VMI |

| Industry |

| Revitalization |

| Fiber |

| packagin |

| Petroleum_Refineries |

| Automotive_industry |

| Smelting |

| spinning |

| Ceramics |

| Glass_Industries |

| Food_industry |

| Ferroalloy_industries |

| Palletization |

| Mining |

| Steel_rolling_industries |

| Power_plant_industries |

| Aluminum_industry |

| Cement_Industry |

| Falcon |

| FLIR |

| FAN |

| Gas_Cooler |

| Steel |

| Condmaster_Ruby |

| Conveyor |

| Compresspr |

| Screw_Compressors |

| Oil_Injected_Screw_Compressor |

| Oil_Free_Screw_Compressors |

| Process_Compressor |

| Regeneration_Compressors |

| Reciprocating_Compressor |

| Rotary_Kiln |

| Gearbox |

| Pelletizing_Gearbox |

| Rolling_Gearbox |

| Matlab |

| Maintenance |

| Authorized_Mobius_Partner |

| Authorized_Mobius_Institute_Partner |

| SCL |

| Rolling |

| Laser_Alignment |

| VMI_Company |

| Rolling_Bearing |

| Journal_Bearing |

TOPICS COVERED – JUNIOR ANALYST CATEGORY I:

| :Maintenance practices |

|---|

| Reactive, preventive, condition-based, proactive |

| How to decide |

| between them |

| :Condition monitoring |

|---|

| Why it works |

| Ultrasound, infrared, oil analysis, wear |

| particle analysis, and electric motor testing |

| :principles of vibration |

|---|

| Waveforms |

| Metrics: overall levels, RMS, P k, Pk-to-Peak, and crest factor |

| :Introduction to vibration measurement |

|---|

| Vibration sensors: displacement, velocity, acceleration |

| Vibration units |

| Mounting: where and how |

| Naming conventions |

| Repeatability and quality |

| Vibration axes: V, H, A, R, and T |

| ?What are “routes” and how do you create them |

| Detecting and avoiding poor data |

| An introduction to the time waveform |

|---|

| :An introduction to the spectrum |

|---|

| An introduction to forcing frequencies |

| A brief introduction to phase |

|---|

| :Signal processing (just the absolute basics) |

|---|

| A quick tour of your analyzer settings |

| Fmax |

| Resolution |

| Spectral averaging |

| :Vibration analysis |

|---|

| The spectrum analysis process |

| What is resonance — a quick introduction |

|---|

| :Diagnosing common fault conditions |

|---|

| Unbalance |

| Misalignment |

| Rolling element bearing failure |

| Looseness |

| Resonance |

| Setting alarm limits |

|---|